Reduce Your Die Attach Costs by Up to 60%!

and Stay Ahead with Industry-Leading Performance

Over 25 years of proven excellence in die attach engineering and precision assembly solutions

maximize production Reduce maintenance, minimize downtime

We are committed to delivering best-in-class systems and application support

Reduce Your Die Attach Costs by Up to 60%!

and Stay Ahead with Industry-Leading Performance

Over 25 years of proven excellence in die attach engineering and precision assembly solutions

maximize production Reduce maintenance, minimize downtime

We are committed to delivering best-in-class systems and application support

Contact us

Reduce Your Die Attach Costs by Up to 60%!

and Stay Ahead with Industry-Leading Performance

Get a personalized demonstration and discover how we can revolutionize your production efficiency.

The MAT Micro Assembly Technologies 6200 and 6500 Die Attach Systems

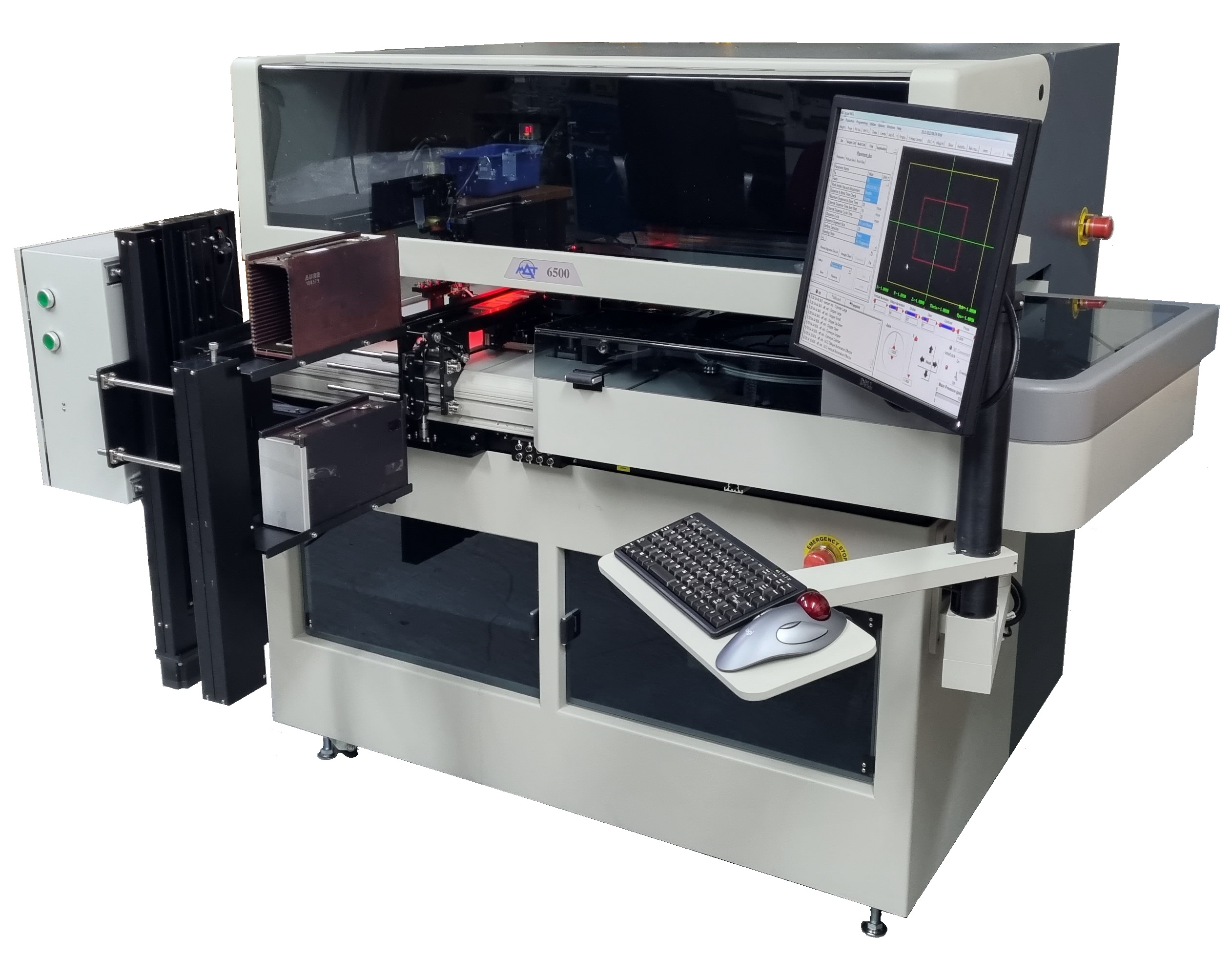

Model 6500

Automatic, High Accuracy Die Attach System

Model 6500 – High Accuracy Meets Ultimate Versatility

Combining industrial performance, advanced automation, and a large work area, the 6500 is the ultimate solution for high-end die attach applications in MCM, RF, MEMS, hybrid, and imaging devices.

Key Advantages

- High Precision Performance: Servo-driven motion systems and digital vision deliver placement accuracy better than ±3 µm, with throughput up to 1000 CPH.

- Large Work Area: Supports substrates up to 20” × 12” while maintaining compact system size (1.2 m² footprint).

- Full Process Versatility: Switch seamlessly between Epoxy, Eutectic, C2/C4, ACF/ACP, and Ag Sintering processes — all built-in and software-selectable.

- Advanced BLT Control: Programmable Bond Line Thickness (BLT) management with height measurement and precision better than 5 µm, independent of adhesive volume.

- Flexible Material Handling: Works with 300 mm wafers, 40 waffle/gel packs, 8 tape & reel feeders, and unusual die aspect ratios.

- Comprehensive Flip-Chip Capability: Chip flipping, bump fluxing, precision alignment, and underfill processes using a high-resolution up-looking camera.

- Wide Process Range: Supports Gold-to-Gold Interconnect (GGI) up to 130 kHz and 40 W, thermo-compression up to 90 N and 500 °C, and local die heating for eutectic MCM bonding.

- Thin & Large Die Handling: Dual-stage ejection system for delicate dies — from 150 µm to over 50 mm, down to 50 µm thickness.

- Smart Process Control: Integrated library for complex adhesive patterns, programmable tool heating, scrubbing motion control, and forming gas option.

- Efficient Design: Weighs 350 kg with deep 50 mm Z-axis travel, offering both precision and stability for complex assemblies

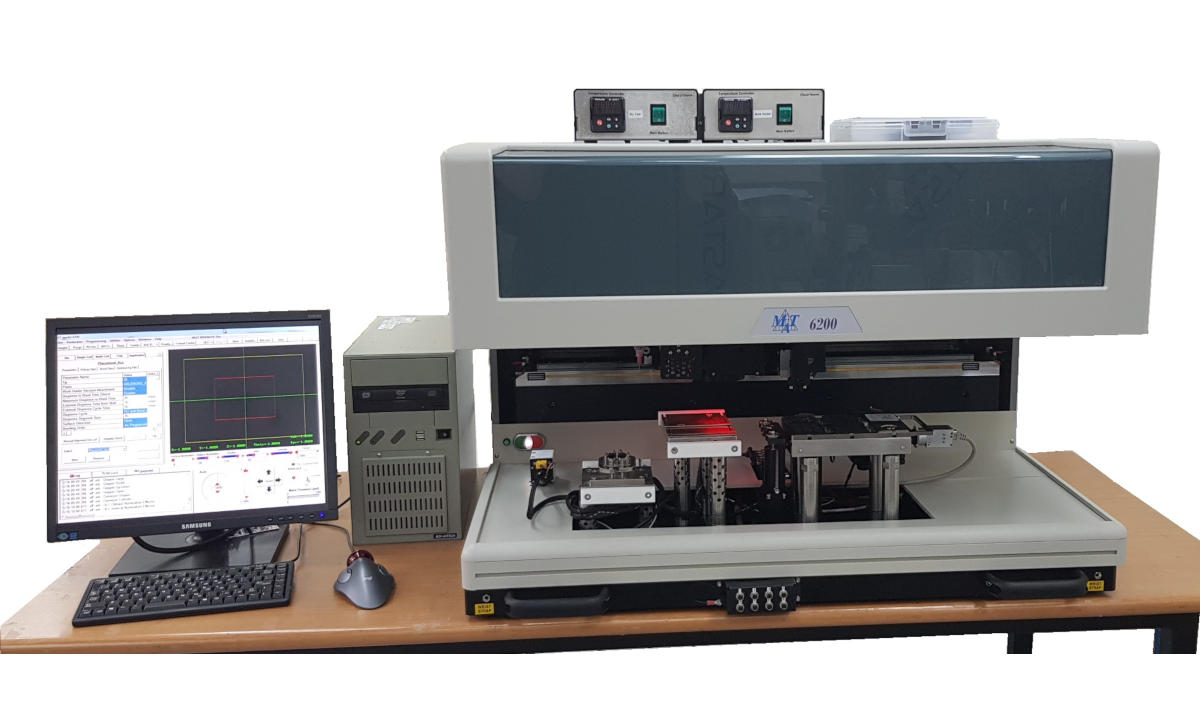

Model 6200

Automatic Die Attach System

Model 6200 – Compact Precision, Unlimited Flexibility

Key Advantages

- High Accuracy & Productivity: Servo-controlled motion with placement precision better than ±3 µm and throughput up to 600 CPH (application dependent).

- Versatile Process Range: Supports MCM, Flip Chip, Eutectic, Silver Glass, Ag Sintering, and multi-chip stacking in a single platform.

- Advanced Vision System: High-resolution digital camera with intelligent image processing ensures repeatable, high-yield results.

- Flexible Dispensing Options: Time-Pressure, Volumetric, or Jet dispensing — with dual dispenser configuration and micro-dot stamping (75 µm).

- Comprehensive Die Handling: Accommodates Waffle/Gel packs, Tape & Reel, Bulk, or mixed feeders for maximum flexibility.

- Flip Chip & High-Temperature Processes: Full C2/C4 support, chip flipping, bump fluxing, precise alignment, and eutectic bonding up to 500 °C with heated tools and forming gas option.

- Compact Table-Top Design: Lightweight system (<200 kg) with 6″ × 6″ work area — suitable for ceramic, silicon, metal, PCB, and other substrates.

The Model 6200 combines precision, reliability, and process versatility — redefining what a compact die attach system can achieve

Contact us

Reduce Your Die Attach Costs by Up to 60%!

and Stay Ahead with Industry-Leading Performance

Get a personalized demonstration and discover how we can revolutionize your production efficiency.

Engineered for Productivity. Built for Reliability. Driven by Precision

- Over 25 years of proven excellence in die attach engineering and precision assembly solutions

- Ensure rapid ROI, Increase productivity, minimize downtime, and reduce maintenance.

- Trusted by hundreds of leading electronics and semiconductor manufacturers across every major industry.

- ISO 9001:2015 certified — guaranteeing world-class quality, safety, and process control.

- Proven process expertise, built through decades of hands-on collaboration with global customers.

Precision. Flexibility. Efficiency — The MAT Advantage

Maximum Savings. Maximum Efficiency.

Reduce die attach operating costs by up to 60% compared to competing systems.

- One modular platform performs all die attach processes — no need for multiple costly machines.

- Exceptional value through precision, speed, and ease of operation.

Unmatched Versatility

- Single platform supports Flip Chip & Face up, Epoxy, Eutectic, Thermo-sonic, Sintering and other technologies large chips, small, active and passive components, and complex bonding.

- Tailor-made flexibility for dynamic industrial requirements.

- Future-proof your investment with modular upgrades.

High Precision for Complex Demands

- Designed for sensitive, high-value applications requiring absolute accuracy.

- Industry-leading accuracy for both small and large chip handling.

- Deliver exceptional quality for complex and precise bonding tasks.

Why choose us?

- Overall solution – machine & tools

- Easy to use, flexible, and reliable tabletop wire bonders

- Application expertise and process optimization

- 24/7 Online Technical support

- Wide Trade-in options

- Extended warranty options

- Global presence

- Over 40 years of experience and know-how

- Silver, Gold, and Platinum service plans

- “Certified Used” MPP machines with warranty

Why Choose Us?

Engineered for Productivity. Built for Reliability. Driven by Precision

- Over 25 years of proven excellence in die attach engineering and precision assembly solutions

- Ensure rapid ROI, Increase productivity, minimize downtime, and reduce maintenance.

- Trusted by hundreds of leading electronics and semiconductor manufacturers across every major industry.

- ISO 9001:2015 certified — guaranteeing world-class quality, safety, and process control.

- Proven process expertise, built through decades of hands-on collaboration with global customers.

Precision. Flexibility. Efficiency — The MAT Advantage

Maximum Savings. Maximum Efficiency.

- Reduce die attach operating costs by up to 60% compared to competing systems.

- One modular platform performs all die attach processes — no need for multiple costly machines.

- Exceptional value through precision, speed, and ease of operation.

Unmatched Versatility

- Single platform supports Flip Chip & Face up, Epoxy, Eutectic, Thermo-sonic, Sintering and other technologies large chips, small, active and passive components, and complex bonding.

- Tailor-made flexibility for dynamic industrial requirements.

- Future-proof your investment with modular upgrades.

High Precision for Complex Demands

- Designed for sensitive, high-value applications requiring absolute accuracy.

- Industry-leading accuracy for both small and large chip handling.

- Deliver exceptional quality for complex and precise bonding tasks.

Global Excellence. Certified Quality. Continuous Support

Global Support & Personalized Service

- Full installation, training, and comprehensive onboarding.

- Tailor-made Pick & Place tools precisely matching your requirements.

- Worldwide service presence ensuring your continuous operation.

Built on Quality. Trusted Worldwide

- Compliant with ISO and strict international quality standards.

- Proven reliability across hundreds of global electronics manufacturers.

- Robust design meets demanding automotive, aerospace, and defense industry standards.

Modular Flexibility

- Customize your setup effortlessly according to changing market needs.

- Easy and affordable upgrades – no replacement machines required.

Who we are

Contact us

Reduce Your Die Attach Costs by Up to 60%!

and Stay Ahead with Industry-Leading Performance

Get a personalized demonstration and discover how we can revolutionize your production efficiency.

All rights reserved 2025 (c) Micro Point Pro Ltd.